ABOUT ZT FAN

Jiangsu ZT Fan Co., Ltd.

Jiangsu ZT Fan Co., Ltd. was founded in 1985 and officially registered in 1990, with a history of over 30 years. The company currently occupies an area of more than 20,000 square meters, with four standard workshops and a research and development testing center, with an annual production capacity of over 1,500 units.

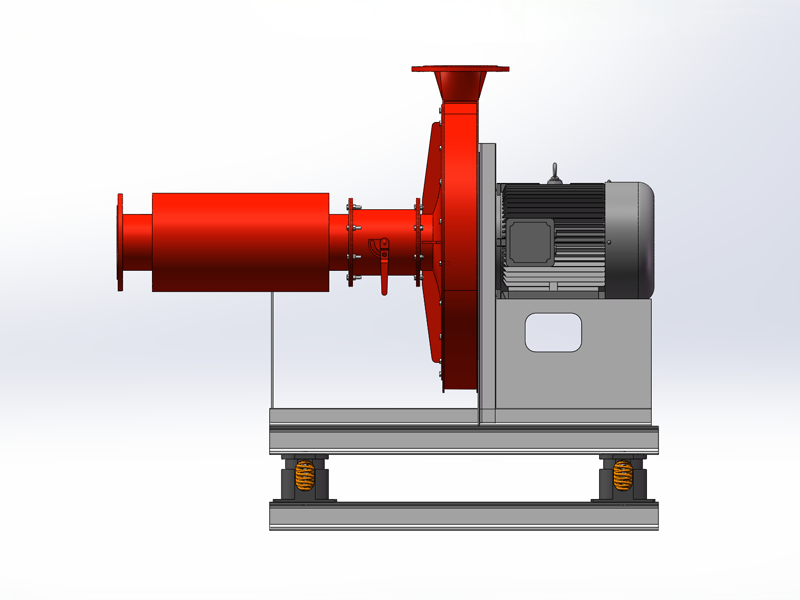

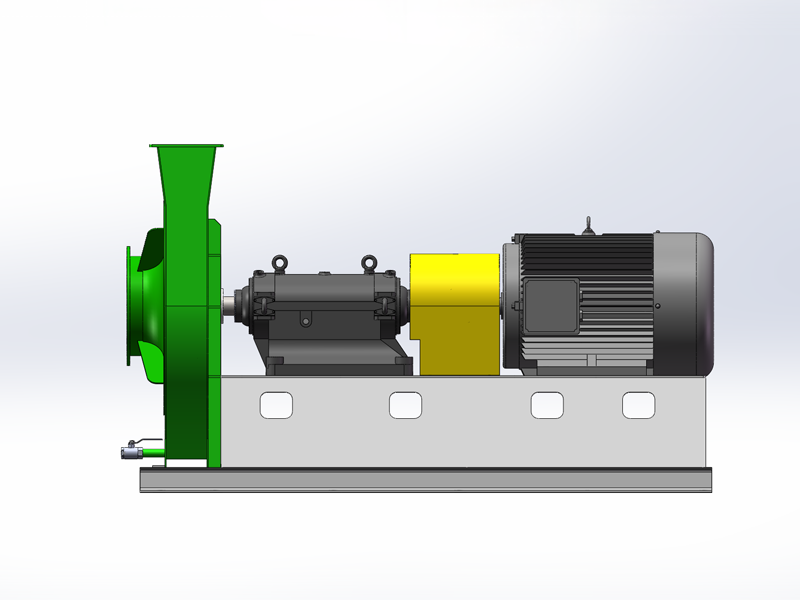

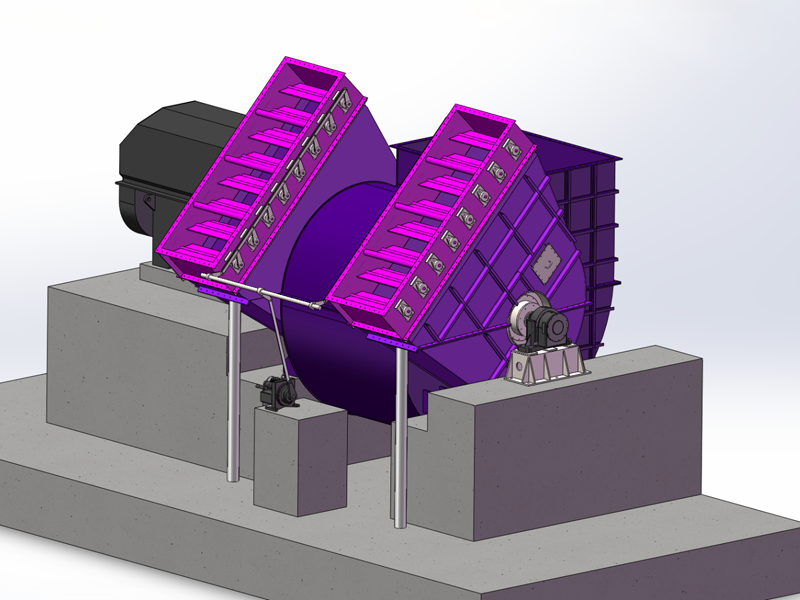

Our company specializes in the production of centrifugal fans, offering a full range of models and specifications to meet various working conditions. They can be used for conveying clean air as well as gases with complex components. In addition to standard products, our company can also customize products according to user requirements to meet different working conditions.

Establish in

Production capacity

Industry experience

Products

The main industries that use our company's centrifugal fans include: environmental protection, combustion, boilers, pharmaceuticals, chemicals, metallurgy, power generation, food, kilns, painting, and so on.

Quickly find what you need

Can't find the product you need? Please feedback us

Continuously create greater value for customers

Explore and Innovate

Customer trust choice

With professional production equipment, testing instruments, and technical teams, we continuously improve product quality and after-sales service, enhance company reputation, and lay a solid foundation for the steady development of the company.

News Center

2023-07-12

The difference between stainless steel fans and high-pressure oxygen supply fans

2023-06-27

The principle and application of oxygen-enriched high-pressure blowers

2023-06-12