Classification and Use of Fan Silencers

Release time:

2022-07-03

The silencer is an absorption type silencer, which is generally divided into straight pipe type, plate type, baffle type, honeycomb type, sound flow type, maze type, elbow type, etc., based on the different structures of the airflow passage. The centrifugal fan silencer is mainly used for various air dynamic noise from various inlet and outlet air ducts of high-pressure centrifugal exhaust fans. It is a well-structured, easy-to-install high air resistance honeycomb silencer.

1. Overview of Induced Draft Fan Silencers:

Induced Draft FanSilencers, fan silencers, and blower silencers all use the principle of sound absorption to reduce noise, effectively addressing mid to high frequency broadband characteristics, as well as low frequency, mid frequency, and pulsation characteristics, including micro-perforated silencers and impedance composite silencers. Fan silencers can be categorized into several types: centrifugal fan silencers, Roots fan silencers, blower silencers, and axial flow fan silencers. Resistance silencers are a type of absorptive silencer. Resistance silencers are a type of absorptive silencer, generally classified into straight pipe, plate, folded plate, honeycomb, sound flow, labyrinth, and elbow types based on the structure of the airflow passage. Resistance silencers are widely used in all types of silencers.

Resistive silencers differ from absorptive silencers in their noise reduction principles. They do not directly absorb sound energy but utilize abrupt interfaces in the pipeline or adjacent resonance chambers to reflect and interfere with sound waves at the abrupt interface. This allows certain frequency sound waves to propagate through the pipeline, achieving the purpose of noise reduction, and can be divided into expansion chamber silencers and resonance silencers.

In practical noise control engineering, noise is often broadband. To control high-intensity broadband noise, it is common to combine resistive sound absorption and resistive noise reduction structures.

2. Classification and Uses of Induced Draft Fan Silencers:

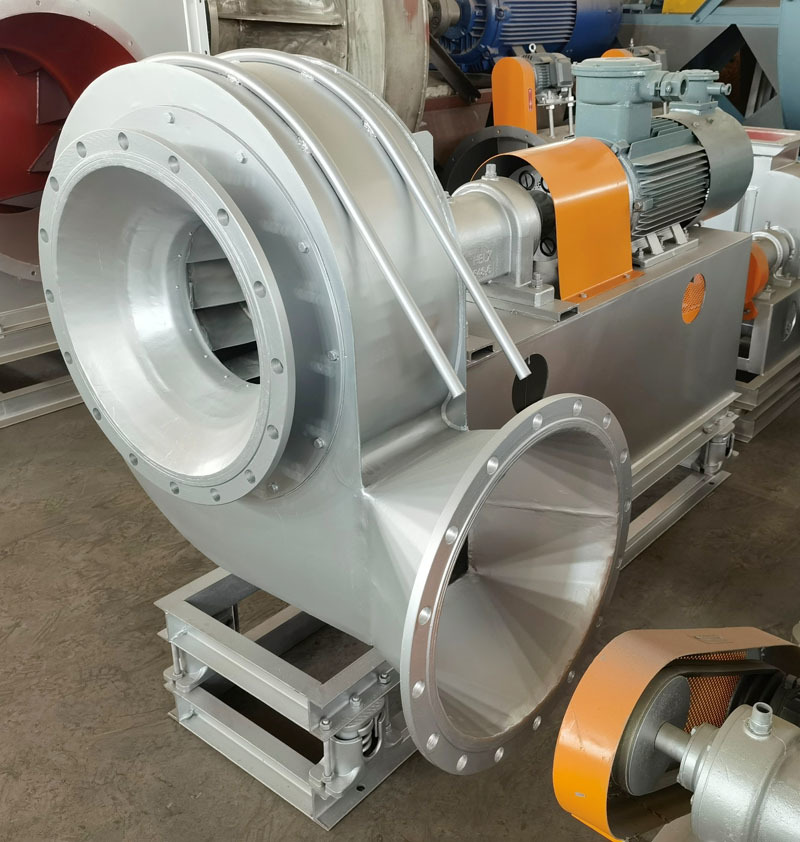

1: Centrifugal Fan Silencer:

Centrifugal induced draft fan silencers are mainly used for various air dynamic noise from high-pressure centrifugal fans at various intake and exhaust ports. Their principle is developed based on the sound absorption principle of resistance plates. This silencer has excellent acoustic performance and good aerodynamic performance; it is a well-structured, easy-to-install high-resistance honeycomb silencer. The resistive section uses a multi-chamber resistive rubber straight pipe channel and cross-shaped sound-absorbing plates to ensure sufficient noise reduction capability across a wide frequency range.

Roots Fan Silencer:

Roots BlowerInduced Draft FanSilencers are used to reduce the intake and exhaust noise of Roots blowers or blowers. They can also be used to reduce the noise of high-pressure fans such as exhaust pipes. Roots fan silencers have a simple structure, are lightweight, use fewer materials, have an attractive shape, are easy to install, and are fireproof. Under the same fan flow conditions, this series of silencers is also suitable for the intake and exhaust of ordinary high-pressure fans.

3: Application Range of Fan Silencers:

Fans are a type of general mechanical equipment with a wide range of applications. Fans cannot be separated from the production processes in industries such as electricity, mining, machinery, metallurgy, and chemical engineering. The noise generated by fans during operation often becomes a hazard affecting worker health and disturbing the environment. In recent years, the industrial sector in China has been a major target for noise pollution control, especially for fans near residential areas, where the aerodynamic noise radiated from the intake and exhaust ports is a major factor in environmental pollution.

Industrial fans are continuous operation equipment. The noise standard set by the International Organization for Standardization (ISO) is ≤90 decibels, and China's new standard is the same, which is the basis for industrial enterprises to meet continuous noise standards. However, without noise reduction measures, the noise generated by the fan's intake and exhaust ports can reach 110-120 decibels, significantly exceeding the standard requirements.

Related News